Digital Twins and Simulations: Transforming Business Processes and Operations in Ports

In the era of Industry 4.0, businesses are turning to new technologies to become smarter and more efficient. Two of these technologies, digital twins and simulations, stand out as powerful tools that can radically change business processes. In this article, we will examine in detail what digital twins and simulations are, how they work, how they are used in the business world, and specifically how they can be used in ports.

A digital twin is the creation of a one-to-one replica of any object, device, service, or physical entity (such as a city, a product, a machine, or a port operation) in a digital environment without physically constructing it.

Digital twins can update real-world data in real-time through sensors, IoT (Internet of Things), and other data sources. This allows digital twins to mirror the real world. The data analyzed by digital twins reveals potential outcomes and enables preventive actions to be taken without the risk and without actual problems occurring.

One of the most important features of digital twins is their dynamic nature; as real-time data changes, so do digital twins. This provides significant advantages in analyzing possible outcomes due to real-time changes.

Key use cases for digital twins include:

Manufacturing: Digital twins in manufacturing facilities can enhance production line efficiency. Real-time data can optimize production processes and improve product quality.

Energy: Energy plants and grids can be better managed through digital twins. This can increase energy efficiency and predict failures in advance.

Healthcare: In the healthcare sector, digital twins created from patient data are used to treat patients and improve healthcare services.

City Planning: Cities can use digital twins to simulate complex systems like traffic flow, energy consumption, and disaster management. This can help cities become more sustainable and secure.

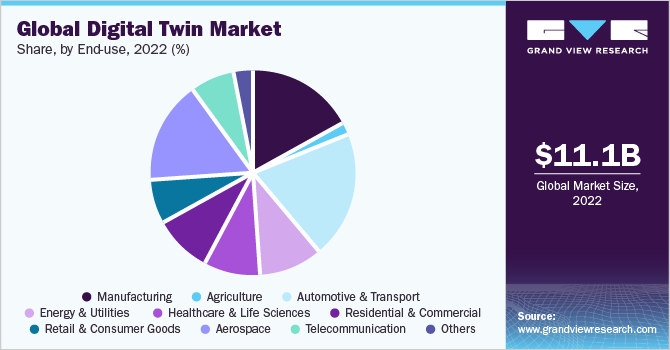

In addition to these, many applications have been developed in sectors such as aerospace, defense, automotive, and transportation to increase efficiency and reduce risks. Digital twin technology is one of the most significant technologies of the Fourth Industrial Revolution. As technologies like sensors, IoT, and big data analytics grow, digital twin technology is advancing rapidly. The main drivers of this growth include a focus on cost reduction in the face of increased competition, optimized and efficient operations, and faster market entry of goods and services. As a result, investments in digital twin technology are making a global impact.

The Digital Twin Market Size Will Reach $155.84 Billion by 2030

According to a new study by Grand View Research Inc., the global digital twin market is expected to reach $155.84 billion by 2030, with a Compound Annual Growth Rate (CAGR) of 37.5% from 2023 to 2030.

https://www.grandviewresearch.com/press-release/global-digital-twin-market

Digital Twins and Decision Support Systems

Digital twins are also used to simulate real-world objects or services. Simulations are designed to model and analyze complex systems in the real world. This makes it easier to understand and improve real-world situations while eliminating all possible risks.

The basic elements of simulations include models, data, data criteria, analysis, and optimization.

Models represent objects, processes, and systems in the real world.

Data and data criteria use real-time data or possible data to produce possible outcomes from simulations.

Analysis and optimization evaluate the results of the simulation and create accurate, real-time decision support systems.

The Use of Digital Twins and Simulation Technology in Ports

In 2021, global trade in goods and services reached $27.3 trillion, a 24% increase from 2020. According to 2021 data, the transportation sector, with a trade volume of $1.37 trillion and the shipping industry, employing more than 1.5 million people directly, play a significant role in world trade. (https://www.wto.org/english/res_e/booksp_e/wtsr_2022_c2_e.pdf)

Ports, which are the main arteries of global trade, are managed with complex operations. Digital twin and simulation technologies offer port operators the opportunity to make their operations more efficient, secure, and environmentally friendly.

With digital twin technology, 3D virtual replicas of physical assets such as ships, cranes, vehicles, equipment, containers, and other cargo can be created. These models can include all physical units of the port, such as port gates, storage areas, and CFS areas. Data from sources such as weather conditions, IoT, sensors, and third parties can be monitored in the digital twin. A port with a digital twin can monitor its port, regardless of its location, in real scale and real-time.

Digital twins supported by simulation algorithms can create possible operational processes using past and real-time data without performing operational processes.

Digital twins and simulation technologies offer port operators the opportunity to reduce risks, optimize operations, and be prepared for the future. These technologies are a significant part of the transformation in the port industry and will play a key role in making ports more efficient, secure, and environmentally friendly.

A port using digital twin and simulation technology can:

Reduce Risks: Potential hazards can be identified in advance, ensuring occupational safety. It also reduces risks such as accidents and equipment breakdowns.

Improve Operational Performance: When operations are simulated, possible operational bottlenecks can be predicted and optimized.

Enable Capacity and Site Planning: Changes in capacity can be predicted in advance with existing or estimated data, allowing for optimal planning.

Traffic Management: On-site traffic is one of the most significant challenges faced by many ports every day. Digital twin and simulation algorithms predict possible traffic congestion in advance, allowing preventive measures to be taken.

Cost Control: Real-time data generated from sensors, IoT, or third-party units enables digital twin technology to predict the costs of units in possible scenarios. This allows ports to make accurate cost or investment decisions.

Operational Cost and Performance Relationship: The cost and performance relationship during port operations can be easily viewed through digital twin technology. It allows managers to make decisions based on different equipment and teams or changing data criteria.

Environmental Sustainability: Digital twins can increase the sustainability of ports by simulating energy efficiency and environmental impacts. Real-time data analysis from sensors and other devices can simulate the most efficient and environmentally friendly possible outcomes.